Related Products

More items about high temperature cable

Shenzhen Test Technology Co., Ltd.

Testeck-Cable is a company specializing in providing high-temperature, lightweight, miniaturized, special and integrated solutions for cable through-wall sealing for industrial fields.Cable through wall sealing is a kind of non-damage"building blocks" new sealing method; replacing the traditional Fireproof mud, fireproof glue, metal waterproof joints, etc.The company followsISO9001,TS22163( span>International Railway Quality Management System)、ISO13485(Medical device quality management system), engaged in independent research and development, manufacturing and sales, the company has A number of technical teams and quality teams engaged in the field of industrial cables for more than 10years, The cable through wall sealing component is made by 20multiple space sealing experts The team is made up of components and continues to innovate based on the actual working conditions of the customers.The product line mainly includes instrumentation (sensor) cables, low smoke Halogen-free flame retardant, data cable, multi-functional integrated cable, spring wire, high temperature series cable, etc.

Application areas include aerospace, rail transit, clean energy (wind power, nuclear power, Photovoltaic, hydropower), automotive industrial vehicles, instrumentation, sensor technology etc.

Characteristics of high temperature cables

Temperature range: High temperature cables are designed to operate in a wide range of temperatures, with some able to withstand temperatures as high as 2000°C.

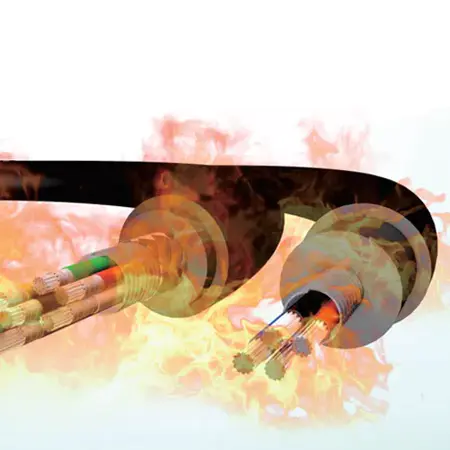

Insulation and jacketing materials: High temperature cables use materials that are designed to withstand high temperatures and resist degradation, such as silicone rubber, PTFE, and ceramic fiber.

Resistance to flame and chemicals: High temperature cables are often treated with flame-retardant materials and are resistant to chemical exposure, making them suitable for use in harsh industrial and chemical environments.

Durability: High temperature cables are typically designed to withstand mechanical stress, bending, and abrasion, and may incorporate features such as armored jackets or braided shields to enhance their durability.

What industries are high temperature cables used in?

-

Aerospace: High temperature cables are used in aerospace applications to connect equipment and sensors in high-temperature environments, such as engines and propulsion systems.

-

Automotive: High temperature cables are used in automotive applications to connect sensors and other electronic components in engines and exhaust systems, where they are exposed to high temperatures and harsh operating conditions.

-

Oil and gas: High temperature cables are used in the oil and gas industry to connect equipment in drilling rigs, pipelines, and refineries, where they are exposed to high temperatures and chemical exposure.

-

Manufacturing: High temperature cables are used in a range of manufacturing applications, including ovens, furnaces, and industrial machinery, where they provide a reliable connection for sensors, probes, and other electronic equipment.

-

Military and defense: High temperature cables are used in military and defense applications to connect equipment and sensors in high-temperature environments, such as aircraft engines and missile systems.

-

Power generation: High temperature cables are used in power generation applications to connect equipment in high-temperature environments, such as turbines and generators.

Advantages of high temperature cables

Heat Resistance: High temperature cables are designed to withstand extreme temperatures, making them ideal for common high temperature applications. Depending on the specific cable type, these cables can operate reliably in temperatures ranging from several hundred to over 2000°C

Durable: High temperature cables are made with materials designed to withstand mechanical stress, bending and abrasion, making them more durable and longer lasting than other cables

Chemical resistance: High temperature cables are generally resistant to chemicals and solvents, making them ideal for use in industries such as oil and gas where exposure to harsh chemicals is common

Excellent Insulation: High temperature cables use specially designed insulation materials that can withstand high temperatures and resist thermal damage, providing excellent insulation performance and ensuring safe and reliable operation

EMI/RFI Shielding: High temperature cables can incorporate Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) shielding to reduce the effects of EMI and ensure reliable and accurate signal transmission through the cable.

Versatile: High temperature cables are available in a variety of types and sizes for a wide range of applications and industries.

Frequently Asked Question

Do you have any question?

FEP High Temperature Flat Ribbon Cable is designed to withstand extreme temperatures, typically ranging from -200°C to +200°C.

The key advantages of FEP High Temperature Flat Ribbon Cable include excellent thermal stability, resistance to chemicals and solvents, high dielectric strength, low friction, moisture resistance, and abrasion resistance. Additionally, its flat ribbon configuration allows for easy installation and management.

FEP High Temperature Flat Ribbon Cable finds applications in various industries such as aerospace, automotive, industrial machinery, electronics, telecommunications, and many more. Its ability to withstand extreme temperatures and provide reliable performance makes it suitable for demanding environments.

Yes, FEP High Temperature Flat Ribbon Cable is well-suited for flexible wiring applications. Its flat ribbon configuration allows for easy bending and routing, making it ideal for applications that require space-saving and flexible wiring solutions.

Yes, FEP High Temperature Flat Ribbon Cable often complies with industry standards and certifications such as UL (Underwriters Laboratories) listings, RoHS (Restriction of Hazardous Substances) compliance, and specific standards set by aerospace or automotive organizations, depending on the intended application.