Related Products

More items about lszh cable

Shenzhen Test Technology Co., Ltd.

Testeck-Cable is a company specializing in providing high-temperature, lightweight, miniaturized, special and integrated solutions for cable through-wall sealing for industrial fields.Cable through wall sealing is a kind of non-damage"building blocks" new sealing method; replacing the traditional Fireproof mud, fireproof glue, metal waterproof joints, etc.The company followsISO9001,TS22163( span>International Railway Quality Management System)、ISO13485(Medical device quality management system), engaged in independent research and development, manufacturing and sales, the company has A number of technical teams and quality teams engaged in the field of industrial cables for more than 10years, The cable through wall sealing component is made by 20multiple space sealing experts The team is made up of components and continues to innovate based on the actual working conditions of the customers.The product line mainly includes instrumentation (sensor) cables, low smoke Halogen-free flame retardant, data cable, multi-functional integrated cable, spring wire, high temperature series cable, etc.

Application areas include aerospace, rail transit, clean energy (wind power, nuclear power, Photovoltaic, hydropower), automotive industrial vehicles, instrumentation, sensor technology etc.

Low temperature series

Low Temperature Series

REFERENCE STANDARD

GJB773A :2000

IEC 1156

Q/TST-05-2018

PRODUCT CHARACTERISTICS

1. Low temperature grade: -60, -70℃, -100℃, -190℃

1. Rated voltage: 300V 600V 1000V

2. Square section: (32AWG-240mm2)

3. Number of cable cores: 1-48 cores

4. Conductor: tin-plated, silver-plated, nickel-plated, bare copper, alloy

5. Bending radius 6D (special requirements)

APPLICATION

This series of cables is suitable for connecting cables of extremely low temperature (liquid nitrogen) sensors, and has long-term oil resistance, acid and alkali resistance, corrosion resistance, and ultraviolet resistance. Field induction.

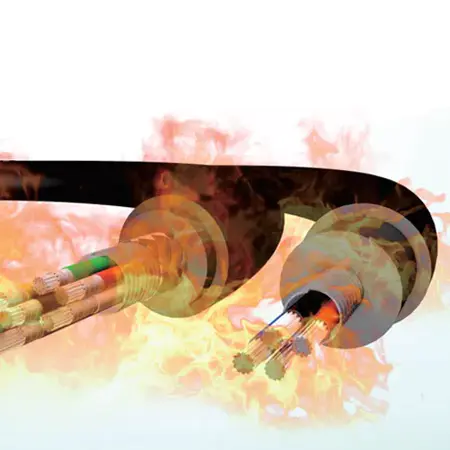

Low smoke halogen free flame retardant cable

Low smoke halogen free flame retardant cable

REFERENCE STANDARD

TB/T1484

GB/T12706-2008

GB/T9330-2008,

GB/T5023-2008,

GB/T19666-2005

PRODUCT CHARACTERISTICS

1. Voltage level: 300V, 600V, 1800V, 3600V

2. Temperature resistance range: -40-125℃, -60-200℃

3. Conductor material: tin-plated, silver-plated

4. Section square: 0.5~240mm2

5. Number of cable cores: 1-48 cores

6. Flame retardant grade: Class A, Class B, Class C

7. Meet the fire protection standard of EN45545-2.

APPLICATION

Low-smoke halogen-free wires and cables produce very little smoke in the case of flame combustion, and the released gas does not contain halogen elements, is non-toxic, and meets the European fire protection standard of EN45545-2. When a fire occurs, it can greatly reduce the damage to instruments, equipment and human body. Hazard, widely used in high-rise buildings, hospitals, large libraries, gymnasiums, disaster prevention command and dispatch buildings, stations and civil airports, passenger waiting rooms, key cultural relics protection sites, and subways, underground shopping malls or densely populated public places.

EV charging cable series

EV Charging Cable Series

REFERENCE STANDARD

IEC62893

EN50260

UL62

GB/T33594

CQC1103-1105

PRODUCT CHARACTERISTICS

1. Rated voltage: AC 450/750V, DC 1.0KV

2. Section square: 0.75mm2, 1.5mm2, 2.5mm2, 4.0mm2, 6.0mm2, 16mm2, 20mm2, 35mm2, 50mm2, 80mm2

3. Number of cable cores: signal line + control line + power line

4. Conductor: Class 5 and Class 6 soft conductors

5. Bending radius 5D (special requirements)

APPLICATION

The electric vehicle charging cable is used to connect the electric vehicle charging device and the charging infrastructure, so as to transmit power to the electric vehicle, and is equipped with a certain number of signal lines, control lines, power auxiliary lines, etc. to ensure accurate control and safe operation of the entire charging process. . Charging cables are generally used in charging stations, parking lots, hotels, communities, garages and other areas, and portable charging cables can be placed in the car.

Frequently Asked Question

Do you have any question?

LSZH stands for Low Smoke Zero Halogen.

The purpose of using LSZH cables is to reduce the emission of harmful smoke and toxic gases in the event of a fire.

LSZH cables are commonly used in applications where there is a risk of fire, such as in public buildings, transportation systems, and data centers.

The main difference between LSZH and PVC cables is that LSZH cables emit little to no smoke or toxic fumes when exposed to fire, while PVC cables emit large amounts of smoke and toxic gases when burned.